What is COPQ? The ultimate guide to calculating, understanding and reducing your costs of poor quality

Cost of Poor Quality (COPQ) is essential to understand for any organization that prioritizes – or wants to prioritize – quality. But what exactly is COPQ and how does it impact your business?

COPQ is a crucial business metric used by companies around the world. It determines the costs that would disappear if all failures were removed from a product, service, or process and is measured either as a percentage of sales or total costs. To achieve a more efficient, resilient, and profitable business, it’s important to understand what COPQ means, its significance, and how your team can calculate it.

COPQ also ties closely with continuous improvement. If all those failures were to disappear, there is no doubt you could see that as an improvement, right? Therefore, having an idea of the Cost of Poor Quality in your organization can make the business case for pursuing continuous improvement extremely clear.

Why have a cost of poor quality (COPQ) calculation?

A company's COPQ is the total sum of the associated costs which are lost due to failure. This includes all waste and variation, overheads to fix the issue, rework costs, as well as lost opportunities such as churned customers or reputational damage.

Successful companies are constantly trying to reduce the Cost of Poor Quality – not just to be more profitable, but because it's a sign of the health and sustainability of your business. When unaddressed, COPQ can be incredibly destructive to the bottom line of the business. In fact, for many businesses, the COPQ can even exceed profits.

COPQ is estimated to be around 20% or more of the costs of goods sold. It's also estimated that around 20 percent of an organization’s direct costs are the result of poor quality – primarily due to overuse, misuse, and waste.

By calculating COPQ, you can show management teams just how much poor quality has inflated their costs and consequently reduces their profits, demonstrating your impact on the bottom line. This makes it very easy to get the appropriate stakeholders to buy in to the sort of continuous improvement that will drastically reduce your COPQ.

Furthermore, detailed COPQ calculations provide a road map for rooting out avoidable costs and focusing on specific areas that are in need of improvement. COPQ can be looked at as the ultimate justification for making improvements to efficiency, overhauling processes, and ultimately enshrining high standards of quality.

COPQ vs. cost reduction

Cost of Poor Quality should not be confused with cost reduction. By confusing the two, you can easily miss the real issues in how your organization is running.

Organizations will often overlook the enormous costs associated with poor performance of products, services, and processes. This causes a whole raft of issues, such as not meeting customer requirements, not providing products or services on time, or having to rework them to meet customer needs.

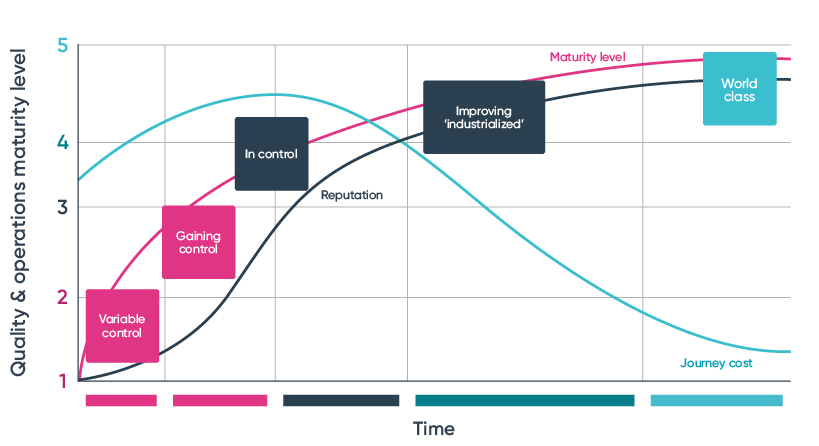

With the Cost of Poor Quality (COPQ) calculation, you aim to improve the maturity of your management system over time so that the costs will eventually reduce. The best quality doesn't really cost more. It ends up costing less if you use core principles – known as cost of value.

In the words of John Oakland of Oakland Consulting: “Failure costs a fortune. Getting up the curve takes a lot of investment as well. That is costing your business a lot of money.”

Consider this: If your business processes and systems are operating successfully, you don't have to dedicate as many resources to fixing business issues. Quality teams can then spend their time optimizing and continually improving strategy – rather than fixing operational issues. Furthermore, the results of COPQ studies become powerful drivers of new breakthrough projects because they identify specific areas in need of improvement.

How to calculate COPQ

Materials and tools for gathering information about your organization’s internal functioning are widely available and easy to use. Ideagen Quality Management software is an example of a powerful tool you can use to easily work out COPQ. Tools like Ideagen QMS can calculate:

Material cost

- Scrap cost

- Rework cost

- Downtime

- Excess inventory

Time

- CAPA metrics

- Complaint handling time

- Rework time

Reputation

- Customer churn: (Lifetime value of customer and customer acquisition cost)

- Employee morale (NPS / Kiosk scores)

- Production

COPQ formula

Determine the time period that you're evaluating – this will narrow the scope of your data. However you will want to pick a time period that is at least going to give you representative data when calculating COPQ, so don’t make it too narrow.

Then add together the total waste / variation and multiply that by the amount of time spent fixing an issue. The result value should be your company's Cost of Poor Quality.

COPQ = (Waste (materials) + defects (variation occurrence))* inefficiencies (time spent fixing)

How Ideagen helps you monitor Cost of Poor Quality (COPQ)

Ideagen Quality Management helps reduce the Cost of Poor Quality for enterprise companies such as Sodexo, Diageo, Honeywell, British Gypsum, and communications giant BT Global Services.

Here are a few ways Ideagen Quality Management gives you insights into your Cost of Poor Quality to ensure it's a tangible business metric you can track over time:

Monitor the trends: Use a business intelligence dashboard to keep a close eye on trends, common issues and weaknesses in your management system. You can easily identify key areas for improvement when such data is visualized and easily accessible

Identify process failures: Complete visibility into failure to meet the requirements in any part of a quality chain has a way of multiplying and a failure in one part of the system creates problems elsewhere. This leads to yet more failure and more problems. Ideagen Quality Management enables your teams to see the entire process and drill into weak areas.

Productivity effect of quality: Ideagen Quality Management enables you to use more proactive methods to view the process – enabling you to get it right the first time. A “right-first-time” approach is core to continual improvement and thus reducing the Cost of Poor Quality.

These are just a handful of the ways Ideagen Quality Management can help your organization to better understand and act on COPQ. But as an all-in-one solution for quality, Ideagen QMS software does so much more. To understand what it can do for your organization, request a demo with our experts today.

Aaron is an experienced content writer specializing in quality and compliance, with a focus on regulatory standards and enhancing operational practices. With a strong background in the life sciences and manufacturing industries, he excels at creating clear, impactful content that supports organizations in achieving sustainable excellence and meeting complex industry requirements.